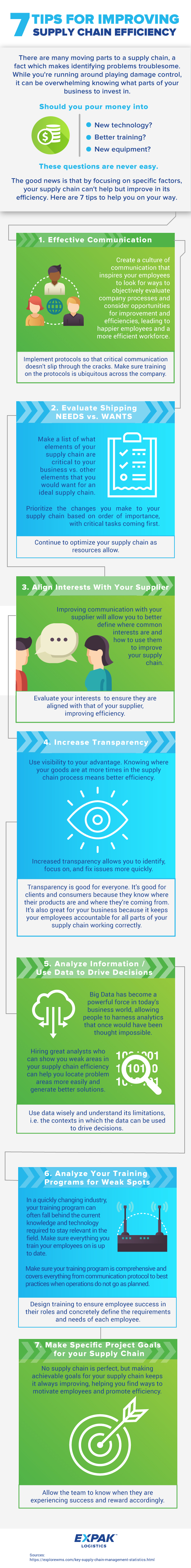

There are many moving parts to a supply chain, a fact which makes identifying problems troublesome. While you’re running around playing damage control, it can be overwhelming knowing what parts of your business to invest in. Should you pour money into new technology? Better training? New equipment? These questions are never easy.

The good news is that by focusing on specific factors, your supply chain can’t help but improve in its efficiency. Here are 7 tips to help you on your way.

Share this Image On Your Site

7 tips For Improving Supply Chain Efficiency

1. Effective Communication

- Create a culture of communication that inspires your employees to look for ways to objectively evaluate company processes and consider opportunities for improvement and efficiencies, leading to happier employees and a more efficient workforce

- Implement protocols so that critical communication doesn’t slip through the cracks. Make sure training on the protocols is ubiquitous across the company

2. Evaluate Shipping Needs vs. Wants

- Make a list of what elements of your supply chain are critical to your business vs. other elements that you would want for an ideal supply chain

- Prioritize the changes you make to your supply chain based on order of importance, with critical tasks coming first

- Continue to optimize your supply chain as resources allow

3. Align Interests With Your Supplier

- Improving communication with your supplier will allow you to better define where common interests are and how to use them to improve your supply chain

- Evaluate your interests to ensure they are aligned with that of your supplier, improving efficiency

4. Increase Transparency

- Use visibility to your advantage. Knowing where your goods are at more times in the supply chain process means better efficiency

- Increased transparency allows you to identify, focus on, and fix issues more quickly

- Transparency is good for everyone. It’s good for clients and consumers because they know where their products are and where they’re coming from. It’s also great for your business because it keeps your employees accountable for all parts of your supply chain working correctly

5. Analyze Information / Use Data to Drive Decisions

- Big Data has become a powerful force in today’s business world, allowing people to harness analytics that once would have been thought impossible

- Hiring great analysts who can show you weak areas in your supply chain efficiency can help you locate problem areas more easily and generate better solutions

- Use data wisely and understand its limitations, i.e. the contexts in which the data can be used to drive decisions

6. Analyze Your Training Programs for Weak Spots

- In a quickly changing industry, your training program can often fall behind the current knowledge and technology required to stay relevant in the field. Make sure everything you train your employees on is up to date

- Make sure your training program is comprehensive and covers everything from communication protocol to best practices when operations do not go as planned

- Design training to ensure employee success in their roles and concretely define the requirements and needs of each employee

7. Make Specific Project Goals for your Supply Chain

- No supply chain is perfect, but making achievable goals for your supply chain keeps it always improving, helping you find ways to motivate employees and promote efficiency

- Allow the team to know when they are experiencing success and reward accordingly